Targeted for specific U.S. regional distribution partners, Uponor is launching TotalFit™ — the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings. Designed for use with PEX, PE-RT, CPVC, and copper piping systems, TotalFit is ideal for service repair, maintenance Read more

PVF

Targeted for specific U.S. regional distribution partners, Uponor is launching TotalFit™ — the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Targeted for specific U.S. regional distribution partners, Uponor is launching TotalFit™ — the professional-grade, engineered polymer (EP), push-to-connect fitting solution that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Designed for use with PEX, PE-RT, CPVC, and copper piping systems, TotalFit is ideal for service repair, maintenance, remodels, and retrofits for potable hot-water and cold-water distribution piping systems in single-family homes, townhomes, apartments, and condominiums.

Featuring patent-pending technology to provide a strong, lasting connection, TotalFit is one of the only full-featured, EP, push-to-connect fittings on the market right now, and it offers about a 30% savings against brass. The new offering includes 33 of the highest-volume push-to-connect fittings in sizes from ½” to 1″ to meet the greatest need in the market.

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer. Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into Read more

John Lebellarte

Milwaukee Valve has announced the retirement of President and CEO Rick Giannini, effective January 20, 2023. John Labellarte, the company’s current COO, will succeed Giannini in leading the commercial, industrial and marine valve manufacturer.

Giannini joined Milwaukee Valve in 1998 and successfully guided the business through challenging market conditions. His leadership transformed Milwaukee Valve into a service leader and global manufacturer. He guided the transformation of the sales organization, reinvested in manufacturing processes and equipment, and assembled the company’s overseas manufacturing operations. Giannini greatly expanded the development and growth of Milwaukee Valve’s product offering and presence in the Navy Marine market.

Giannini also developed and maintained the management team which will continue to lead the company. He dedicated time and energy to industry-leading organizations, serving as Chairman of the Aircraft Carrier Industrial Base Coalition (ACIBC) since its inception in 2004. He also sat on The American Supply Association’s (ASA) Industrial Piping Division Steering Committee and served on ASA’s Board of Directors.

New president and COO John Labellarte started with Milwaukee Valve in 1999 as General Manager. He was promoted to Vice President and COO in 2006. During his tenure, Labellarte has been instrumental in driving the company’s global manufacturing initiatives, strategic planning, product development and operational performance. His focus on continual improvement and the utilization and development of new technologies will continue to build brand value and value proposition for the company. Prior to joining Milwaukee Valve, Labellarte worked for 12 years with the Marpac & McCANNA Valve companies, serving in operations and management roles. He is extremely qualified to lead Milwaukee Valve, with 35 years of executive and operations management experience in the valve industry.

In its 121st year of business, Milwaukee Valve Company is internationally recognized for state-of-the-art manufacturing facilities and innovative new products covering a wide range of commercial and industrial applications.

By Aaron Stotko When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high. That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion Read more

By Aaron Stotko

When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high.

That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion connections to be the ideal system, due to its durability and ease of installation in addition to the job-site productivity, safety and, best of all, profitability potential it provided.

And City Wide Mechanical isn’t alone in their findings. Many mechanical contractors are discovering the benefits of PEX-a pipe and F1960 connections as the preferred alternative to copper, iron, and steel, which have dominated the mechanical piping industry for decades.

Benefits of PEX-a

PEX is an acronym for crosslinked polyethylene. It has been used in North America since the mid-1980s, starting with radiant floor heating systems, then moving into plumbing and, eventually, to hydronic hot-water heating and chilled-water applications.

PEX can be manufactured via three different processes, which create products with varying crosslinking percentages that allow for different characteristics. PEX-a is the most durable, flexible, and resilient with crosslinking around 85%. PEX-b is a stiffer piping product with crosslinking around 65% to 70%, and PEX-c features crosslinking around 70% to 75%.

ASHRAE Headquarters Grand Opening Fall 2021, photos by Devin Abellon

One major benefit of the higher crosslinking in PEX-a is its extreme flexibility along with its thermal and shape memory. The flexibility of PEX-a eliminates most connections in smaller-diameter piping, saving time and money with up to half the connections required in rigid metal piping systems. To make a change in direction, the installer simply bends the pipe instead of having to stop and make a fitting. There are also bend supports available that help hold a bend securely in place.

The thermal memory of PEX-a provides kink repairability with a simple shot of heat from a heat gun. This eliminates the need to add in a coupling if a kink ever occurs in the pipe. (It is important to note that kink repairability is not possible with PEX-b or PEX-c pipe.)

The shape memory of PEX-a allows the pipe to expand and contract back down to its original shape. This makes it extremely resilient in freezing conditions and also provides for the fastest, easiest, most reliable PEX-a fitting system — F1960 expansions.

Expansion fittings require one simple tool to expand the pipe and an expansion ring before inserting a fitting. As the pipe and expansion ring naturally shrink back to their original shape, it creates a strong, durable connection that holds tight and can never be dry-fit. (Note: It is not recommended to expand PEX-b or PEX-c pipe due to microcracking that can occur.)

The innovative expansion fitting method eliminates torches, glues, and solder from a job site for greater worker safety. Plus, the system is extremely easy for installers to learn, helping get new crews up to speed quickly.

Speaking of job-site safety, PEX is also much lighter in weight compared with metal systems. For example, a 300-foot coil of 1/2-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds. The lighter weight of PEX makes it safer and easier for installers to move around a job site and also eliminates the need for heavy-lifting equipment.

PEX-a also has a long-term advantage over copper when it comes to performance longevity. It is a static system, meaning its internal surfaces — which are three times smoother than copper — will not pit, scale, or corrode. That means its performance will remain the same from day one through decades of use.

Finally, because it is not a traded commodity, PEX-a holds a relatively stable material cost. This makes bidding a project much more consistent and reliable.

Application Details and Installation Tips

PEX-a is regulated by the ASTM F876 standard, which denotes temperature and pressure ratings of 200°F at 80 psi (pounds per square inch), 180°F at 100 psi, and 73.4°F at 160 psi. These values are well within the range of operation for most hydronic systems, including chilled beams, fan coil units, baseboards, radiators, hydronic VAV (variable-air volume) reheat coils, and radiant manifolds.

Because PEX is oxygen-permeable, it is important to use a pipe with an oxygen barrier that limits oxygen diffusion to levels below DIN 4726. This will protect the metallic components in the mechanical piping system, such as valves, strainers, and pump volutes, from corrosion.

The pipe is manufactured in sizes from 5/16 inch up to 4 inches and features a copper tube size (CTS) outside diameter. This means all the off-the-shelf components used in a copper hydronic piping system — hangers, supports, and insulation — can be the same.

For horizontal piping, the industry offers PEX-a Pipe Support — a galvanized-steel channel that is 9 feet in length and available in PEX pipe sizes from ½ inch to 3½ inches. This solution enables hanger spacing similar to copper pipe and helps control the natural expansion and contraction of the pipe as it heats and cools.

Because PEX-a expands at 1.1 inches per 100 feet per 10°F Delta T (which is 10 times that of copper), installing anchors every 65 feet and using PEX-a Pipe Supports allows PEX-a to function much like a copper system. In fact, different installation methods have a different effect on the overall net expansion rate.

With a strut-and-clamp system, using PEX-a Pipe Supports and anchoring with fixed points reduces the expansion rate of PEX-a to 0.08 inches per 100 feet per 10°F Delta T (a rate less than copper). And a loop-and-clevis system can reduce the rate to 0.12 inches per 100 feet per 10°F Delta T.

If you’d like to learn more about PEX-a piping systems, visit the Plastics Pipe Institute at plasticpipe.org or the Plastic Pipe and Fittings Association at ppfahome.org.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Apple Valley, Minn. — Uponor North America (Uponor) held a ceremonial “pipe-cutting event” to mark the opening of its $5.5 million, 25,000-square-foot expansion to the Hutchinson, Minn., facility. This new space will increase the company’s PEX-a pipe extrusion production capacity by more than 10 percent, while growing highly skilled jobs in Hutchinson in the coming Read more

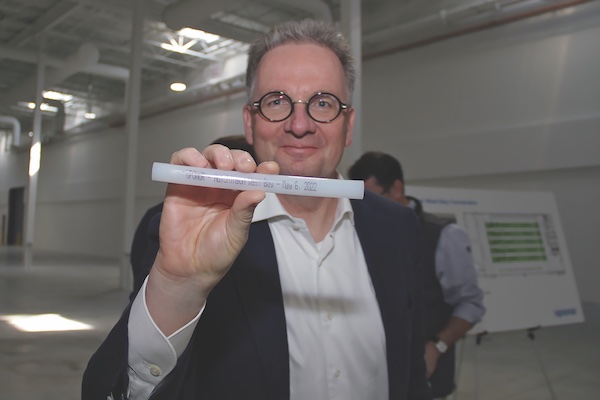

Apple Valley, Minn. — Uponor North America (Uponor) held a ceremonial “pipe-cutting event” to mark the opening of its $5.5 million, 25,000-square-foot expansion to the Hutchinson, Minn., facility. This new space will increase the company’s PEX-a pipe extrusion production capacity by more than 10 percent, while growing highly skilled jobs in Hutchinson in the coming years.

Michael Rauterkus, president and CEO, Uponor Group, (center) joins business leaders as he cuts the ceremonial PEX-a pipe to mark the opening of the company’s $5.5 million, 25,000 sq. ft. expansion in Hutchinson, Minn.

The expansion project broke ground in July 2021 with PCL Construction as the general contractor, Tekton Engineers as the structural engineer, Focal Point Partners as the electrical subcontractor, and Legend Companies as the mechanical subcontractor. The renovated space will allow Uponor to move forward with a major investment in next-generation extrusion technology.

Michael Rauterkus, president and CEO, Uponor Group, took part in the event. This was his first trip to visit Uponor facilities across North America since joining the company in August 2021. He toured the Hutchinson production facility, met with team members, and helped cut the ceremonial pipe.

“Today was a special day for Uponor North America,” Rauterkus said during the event. “Seeing this investment become a reality and knowing what is possible from a manufacturing potential, I am certain Uponor will continue to make positive impacts on the Hutchinson area. I am eager to see what happens next with this team.”

“This expansion reinforces our commitment to Hutchinson and the team members who help us deliver for our customers. I want to thank our construction partners for their efforts in designing and building this space, as well as our global partners across Uponor who saw the potential in what our Hutchinson team could achieve with this major investment,” said Jon Sillerud, vice president, Operations, Uponor North America.

Viega Works online training also will continue. Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1. The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements Read more

Viega Works online training also will continue.

Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1.

The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements when appropriate.

“We’re excited to reopen and welcome back our customers, contractors and distributors,” said Jason McKinnon, director oftechnical services. “We moved training online during the pandemic and that’s been successful, but it’s going to be great to work in-person again with people.”

The seminar centers are located at Viega LLC headquarters in Broomfield, Colo., and in Nashua, N.H. Each features classrooms, hand-on workshops and interactive learning displays. Viega offers courses in a variety of subjects, including pressing, design and installation, and each course is customizable to meet the needs of our customers.

In response to customer demand during the lockdown, the company created Viega Works, online sessions largely limited to single companies. These programs, which can be as short as 30 minutes, are custom designed to cover the topics customers request.

“Customers like Viega Works because it’s fast and affordable and gives them the exact information they need without requiring travel or a major time commitment,” McKinnon said. “With the reopening of our seminar centers we offer even more opportunities to engage with our technical consultants than ever before. Customers can attend in-person at one of our seminar centers or contact us to set up a unique virtual experience with content specific to their team. No matter where or how you want to connect with our experts, we will make it easy and valuable for you and your organization.”